- New board that made in China;

- New printhead XP600;

- No speed limit;

- No printing line anymore;

- Character printing with real effect;

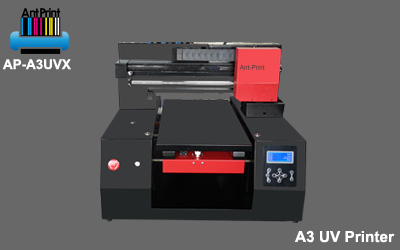

Ant-Print New board AP-A3UVX A3 plus XP600 printer head UV flatbed inkjet printer with industrial production speed

Model: AP-A3UVX

>> Demo Video for printing on acrylic and plastic materials

> Demo Video for printing on several phone covers together

>> Demo Video for printing on jar cylinder

>> Demo Video for printing on dark tshirt by one pass

>> Demo Video for printing on white tshirt

Parameters of AP-A3UVX

| Printing Technology | One Printer head advanced Micro Piezo 6 color pigment inkjet technology |

| Ink colors (6 colors) | Cyan, magenta, yellow, black, white, white |

| Printing speed | 8 pass, 70s/A4 full size |

| Print head | XP600 |

| Max resolution | 16 pass |

| transmit data | Gigabit net |

| Max Printing Size | A3 (330mm×600mm) |

| Max thickness | 200 MM |

| Printer head Protection | Intelligent Self Protect System |

| Ink system | Continue ink supply system with damper cartridge |

| Ink bottle | 6 set Ink Tanks with 500ml or 250ml per bottle |

| Height adjustment | Automation |

| Ink consumption | 10 ML/SQM |

| Voltage/ Power | VAC220/110 ± 10 ,50HZ~60HZ,Power ≤ 35W |

| UV lamp power | 50 W |

| UV lamp Temperature | 60 degree(UV lamp surface)

40 degree (1cm far from lamp surface) |

| Working environment | 10-35 degrees (50°-95°F), humidity 20~80% |

| Head Cleaning method | Automatic / Manual |

| Printer/packing size | 77cm×72cm×60cm / 87*82*76cm |

| Net /Gross weight | 49kg / 75kg |

| Printing Software | Special printing software |

| Computer system | Windows system, Gigabit net,

network adapter contain below character: Gigabit、GBE、10/100/1000M、RTL8169 |

| Ink Type | UV ink/ Textile Ink/ Edible ink |

| Language | English, Chinese |

| Special Remarks | Customized service is available |

| Standard Enclosure | Software 1 set, power line 1 set, Network line 1set, guidebook 1 set |

| Application | Tshirt / phone case / ABS plastic / acylic / metal / glass / ceramic |

| Unit Price |

Advanced Features of Ant-Print AP-A3UVX UV printer

1. Max printing width up to 33cm

Compared to the Epson1390 printer max printing width 28cm, new board A3UV printer max printing size can up to 33*60cm.

2. Three times faster speed

New board printer speed runs three times faster than Epson1390 printer.

The max printing distance (between the printer head to the products surface) will be around 8mm, more 5mm printing distance than Espon1390 printer, so it can print with good quality even on the rough surface.

3. No printing line anymore

Perfect printing quality without printing line anymore. Based on our the new wave mode inkjet printing technology and eclosion function in the special printing software, the inkjet result will not appear printing line anymore, also the printing precision will be more accurate than 1390 printer. What’s more, we already created the perfect ICC profile, which can help clients print character portrait with the real effect.

4. Better performance application on cylinder.

As our board can control the inkjet printhead nozzle quantity, so it can application on more cylinder products, for example, we can print on the smaller cylinder than 3cm diameter with nice accurate precision.

5. Industrial production without errors anymore

As the 1390 printer was refitted with original Epson head and board, and Epson company did the limits for the working time, printing speed and width, if you over this limits, there always appear ink error or Paper Jam that stop your printing jobs. But for our new board printer, it will not appear these errors anymore after we changed the Epson board. Besides, new printer can stop printing any time and continue printing from the stopping point, achieve Industrial production with 24 hours perday.

6. Printing process become more simple and efficient

Start printing from any position and no need printing left right guide line anymore before start printing job. As new printer find the printing position through the grating and pulse signal, so it can print from any position, no need printing from the original sensor position, it can help operator reduce much time while they are waiting for the platform moving to original position.

What’s more, printer can ignore the transparent part image, it will not printing for the transparent part, no need meaningless printing.

7. Servo motor with high printing accurate precision.

Until now, many other suppliers use the stepper motor that can reduce production cost. The enormous advantages of servo motor are incomparable with stepper motor, such as not missing pulse signal, high-speed printing control, volume production for a longer time , heating and so on.

8. Cat.7 network lines with stable communication effectively.

New printer use the Cat.7 network lines to communication between the printer and computer. Compared to the most USB connect lines in the most market, Cat.7 network lines has better performance in the areas of missing the data packets, anti-jamming etc. Until now, it become the most high-end control board transmission signal in the market.

Further more, control board has off memory function, automatic power-off protection function, it can help you save the trouble to re-write data while illegal power off, you just need edit your setting one time and it will not change anymore. That is the amazing new technology of our new control board.

9. Rubber Synchro belt & PU Synchro belt

Our new printer use the rubber synchro belt but not cheaper PU synchro belt. After our hundred times testing, the noise reduction effect performance is more better then PU synchro belt although it is more expensive than PU belt.

New printer also imitates the Epson printer structure that add the grating and carriage synchronous belt spring tightness function, which can improve the printing effect. Printer use the Taiwang HG guide, can reduce the printing noise.

10. All in one Keypad & LED display

All of the operation buttons gather in the same right side, it is very humanitarian for operation.

For the Led display and show you the printing details situation while the printer is working. All in one keypad also add some new functions: Onekey to do the ink suction automatically, Nozzle checking, prints pending, carriage displaced and so on. Operator no need always control the computer anymore, humanized operation make your become very comfortable!

11. Infrared Ray auto-induction

Printer can auto response the height by the infrared ray, press ”Auto” button and the printer platform will adjust the height automatically, after that, products will be fed in automatically. Height adjustment can product the printer head from knocking effectively.

12. More rational design for the LED UV system

For the double head UV printer, every one head work together with special one LED UV lamp, not only one long UV lamp work together with two printer head, which can help you save excess light pollution. For the cooling system use the double water and air cooling methods that can let your UV lamp work for more than 20 thousand hours, the cooling water from pump can be workable for 4m, lifetime can be up to 50 thousand hours. The surface temperature of UV lamp can be kept around 40 degree that will not change original printed materials while it is printing.

13. High voltage filter

New machine has the high voltage filter that can weaken the strong current interference for the weak electric signal, which can improve the stable performance usefully.