Compared To Desktop L805 A4 Flatbed UV Printer, Why Should Buy New Small DX10 Portable UV Printer?

Foreword: DX10 head UV printer model AP-A4pro is a UV printer with independent boards. It uses the main board and nozzle board developed by the domestic people. The nozzles are also the new EPSON DX10 nozzles. It is no longer necessary to use the printer frame on the original EPSON office paper printer. up. The L805 UV printer is an old modified machine, which directly uses the L805 nozzle and EPSON L805 main board from the original EPSON office paper printer, and reinstalls the original EPSON rack on the existing UV printer. The nozzle and the main board are the two core components of the UV printer, because the models and structures of the two are different, and there are very obvious differences in specific use!

Epson a4 dx10 printer head

Since the price and cost of the print head board and the main board of the independent board are much higher than that of the EPSON L805 main board, the comprehensive manufacturing cost is much higher than that of the L805UV printer. A4UV printer for low price products. However, today, considering the dissatisfaction of consumers with the L805 UV printer, our company finally developed and manufactured an upgraded A4 UV flatbed printer AP-A4pro, which is a small negative A4 UV flatbed printer with revolutionary upgrade significance , if you learn and use it, you will love it!

So compared to the old EPSON L805 A4 UV printer, what are the revolutionary upgrades of the new dx10 UV printer?

1. There Is NO any Ink Error Reporting And Paper Jam Reporting Issues Anymore

The L805 A4UV flatbed printer has ink drop key and paper jam key error reports, but the AP-A4pro UV printer does not.

The old desktop EPON L805 UV printer still uses the EPSON L805 nozzle and the EPSON L805 motherboard, so many of it comes from the restrictions of EPSON (you know, EPSON actually prohibits people from using the machine that he originally used for office paper printing to convert into UV printer), for example, there is still ink in the bottle of the machine, but the machine reports an error for no reason; it is obvious that the printed object has been placed on the platform, but the machine still displays a paper input problem, causing the paper jam button to report an error.

Epson L805 printhead UV printer

When the machine reports an error, we must delete the printing tasks in the computer, and the error will disappear after pressing the ink drop button and the paper jam button several times, and the machine can start working again after cutting off the power of the printer and restarting the printer. It’s okay if the machine only reports an error at the beginning of printing, but if an error occurs during printing, the printed object will be scrapped. The point is, we have to waste a lot of time on repairing the machine!

If you observe carefully, you will find that the old style L805 UV machine still has ink drop button and paper jam button, but the new dx10 a4 UV flatbed printer does not have these two buttons, why? Because the newly upgraded small A4UV printer will never have this problem again!

2. The Real Printable Width Format Can Up 21cm, Not Only 16cm

The actual printing width of the L805 A4UV flatbed printer is not 21CM, while the AP-A4pro UV printer no longer has the limitation of the printing width;

Because EPSON has limited the maximum printing format of L805 nozzle and main board, it can only reach 21CM.

However, since the printer itself has UV lamps that occupy the space in the horizontal position, the real maximum printable width is smaller 21cm. The real printable width of most L805 A4UV printers on the market is only 16cm*29cm (although all manufacturers mark the platform size is 21*29cm), and the new small UV flatbed printer AP-A4pro does not have this limitation, so the real printable format can be 100% 21*30CM; the printable height can also reach 12CM;

| Click For More Details For New AP-A4pro with Dx10 Printer head

Welcome to sent ” Inquiry ” to us for the new dx10 AP-A4pro uv printer. We will reply you within 1 hour!

3. Achieve 24 hours/Day Continuous Working, Speed Will Not Become Slow Anymore

new a4 uv keep 24 hours printing

The L805 A4 UV flatbed printer has limited working hours, while the DX10 AP-A4pro UV printer can work 24 hours a day;

If you have operated and modified the L805 A4UV printer, you must have encountered the phenomenon that the printer slows down after printing for an hour or two. In fact, this phenomenon of slowing down also comes from EPSON. Every time there is a slowdown, you need to drop one or two drops of WD40 lubricating oil on the guide rail of the printer, and let the machine rest for half an hour before restarting, and the machine can resume normal work.

Portable Epson Dx10 AP-A4pro is different, because it no longer uses EPSON’s print head and main board, so there is no limitation in this respect. The printer uses a continuous ink supply system, the machine can work uninterrupted throughout the day, just need to add ink normally!

4. No Need To Add The Guide Line Anymore Before Click “Print” In Rip Software

Desktop L805 UV flatbed printer uses AcroRIP8.1.2 or AcroRIP9.0.3 or AcroRIP10.0 version (AcroRIP10.0 is the latest version in 2022, of course there may be a higher version in the future), every time you click print in the software It is necessary to add a guide line to the product, so that the UV lamp will start to work from the rightmost position. The dx10 head small AP-A4pro UV fltbed printer does not need to consider this issue;

5. Print With New Nozzle Flash spray function Protect Nozzles From Clogged

small Dx10 portable AP-A4pro UV printer software has flash spray function, but L805 UV printer does not have this function in the software.

For the newly DX10 upgraded UV printer, the time can be set in the software to allow the nozzle to perform a very small amount of flash spray, so as to better avoid nozzle clogging and keep the nozzle in a smooth and working state at any time; If the old L805 UV printer If it does not work for 2-3 days, the state of the nozzles will be very poor, and the nozzles will be clogged badly; While the DX10 AP-A4Pro UV printer can not work for 15-20 days, as long as it comes back and automatically cleans, the state of the nozzles is still very good!

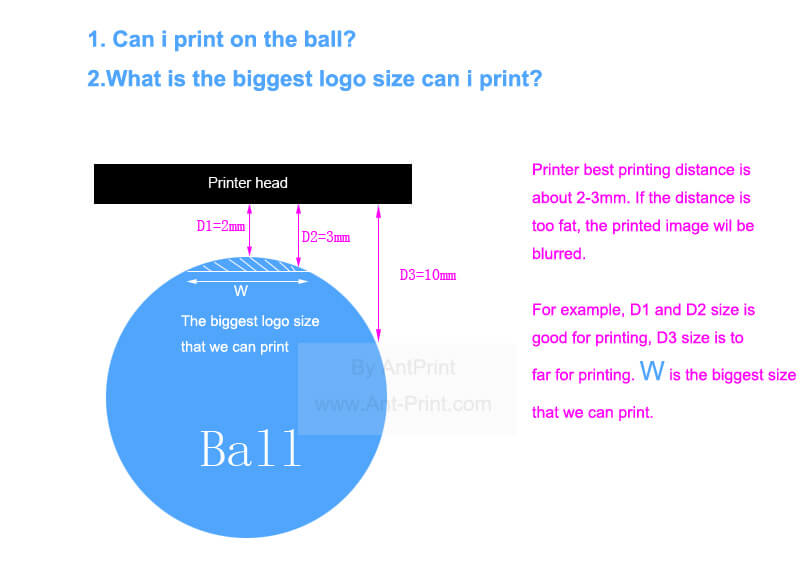

6. The Max Print Distance Up To 4-5mm, Better To Print Curved Products

The biggest printing size for ball

The printing distance of the L805 UV printer is very short at 1-2mm, while the new dx10 AP-A4pro UV flatbed printer has a higher inkjet printing distance, which can reach 4-5mm; so, when you print a product with a slightly curved surface, the L805UV The effect of the printer is not very ideal.

Especially for beginners, if you are not sure about the printing distance, the printed pattern will be very blurred; and the newly upgraded A4UV printer has a higher printable distance, and there will be no UV ink drift just because the printing distance is too far away!

PS: If your printer also print on the cylinder, the bigger max printing distance will be much helpful for you as well. For the details, please learn as the right side picture.

7. Nice Quality For White Ink & Colorful Ink Printing By One Pass

The AP-A4pro UV printer has a more perfect white ink effect, and the white ink effect of the L805UV printer is not very ideal; the newly upgraded UV printer can set the number of times to print white ink at a time, but the L805 UV printer does not have this function;

Moreover, the AP-A4pro Uv machine can realize simultaneous four-color + white (KCMY and white ink) high-speed printing with high-quality and wide color gamut printing, using CMYK ink to achieve four-color high-speed printing, and white ink can be added to facilitate printing of any color material , such as black mobile phone case, black wood, black furniture and any flat material.

8. No Printing Streak Problem Anymore

The printing effect of the L805UV printer is prone to drawing streaks, especially if the nozzle of the L805 is used for 1-2 months, the nozzle is very prone to the problem of drawing streaks;

However, AP-A4proUV printers with DX10 nozzles and independent boards will not have this problem, because of its intelligent wave printing technology: intelligent wave printing technology has greatly improved the phenomenon of Banding and Pass in the traditional printing method, so that Output high-quality product patterns!