10 Important Questions Help You Know What Is dtf Printing ?

Question No.1 What is dtf printing machine ? How does dtf printing work ?

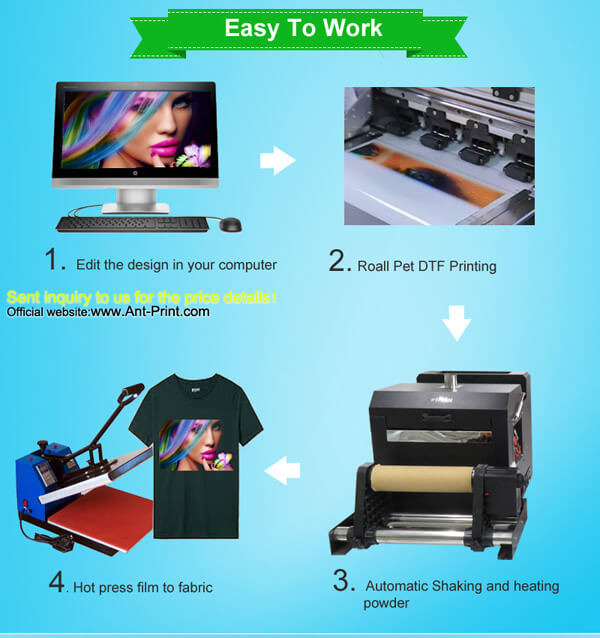

Direct to film (DTF) printing is a relatively new printing technology that allows for high-quality printing onto a variety of materials, including textiles, nylon, cotton and more. A DTF printing machine is a specialized printer that uses DTF technology to print designs onto a film substrate that can then be transferred to the desired material.

The process begins with printing the design onto a special DTF film using a printer equipped with DTF technology. Once the design is printed onto the film, it is then applied to the desired material using a heat press. The heat press applies heat and pressure, causing the ink to transfer from the film to the material.

DTF printing is a cost-effective and efficient printing method that offers high-quality results and can be used to print onto a wide range of materials. It is commonly used in the textile industry to create custom t-shirts, hats, and other apparel, as well as in the printing of promotional items and signage.

Here please watch the DTF Printing Demo Video

If you need more dtf printing working demo videos or testing sample, feel free to contact us!

dtf printer all in one application

Questions No.2 What products are dtf can print ?

DTF printer can be used to print designs on a wide range of materials, including textiles such as t-shirts, hoodies, and bags, jeans, hat etc.

Direct to film printer can produce high-quality prints with a range of colors, gradients, and photographic images. Additionally, DTF printing is a relatively fast and cost-effective printing method, making it suitable for small- to medium-sized businesses or print-on-demand services.

One of the advantages of DTF printing is that it allows for printing on dark-colored fabrics or substrates without requiring the use of an underbase layer, which is typically needed for traditional screen printing or direct-to-garment (DTG) printing.

Questions No.3 What do you need for start a dtf printing business at home?

Starting a DTF printing business from home can be a great way to enter the world of printing and entrepreneurship. Here is our advice before you start your dtf printing business at home:

- Research the market and competition: Before starting your business, you should research the market and competition to understand the demand for DTF printing in your area and the pricing strategies used by other businesses.

- Choose the right equipment

- If you are newer for the dtf printer, we will recommend you the economic version modified DTF Printer, such as Epson head L1800 dtf printer, Epson 1390 DTF Printer, Epson L1900 dtf printer and so on.

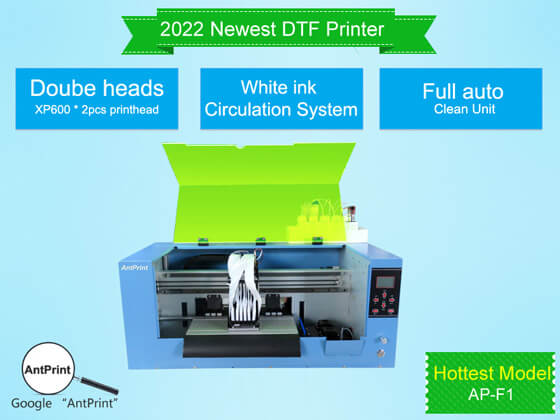

- If you are not a newer, you can consider the Epson Dx9 Double head model dtf printer, because this machine use not only the new printer head model, but also new technology with self-developed mother boards and head boards. So the printing speed and working efficient is much better to help you improve the printing job.

- Create a business plan: A business plan will help you define your goals, target market, pricing, and marketing strategies. You can use online templates or consult with a business advisor to create a comprehensive plan.

- Set up your workspace: You will need a workspace that is suitable for DTF printing, with proper ventilation, lighting, and storage for supplies. You may also need to obtain any necessary permits or licenses for your home-based business.

- Market your business: You can start marketing your business by creating a website, social media pages, and printed materials like business cards and flyers. You can also reach out to local businesses, schools, and organizations to offer your DTF printing services.

- Build your brand: Building a strong brand is important for any business. You can create a brand that reflects your values, mission, and target market. You can also differentiate yourself from the competition by offering unique designs, fast turnaround times, and excellent customer service.

Starting a DTF printing business from home requires dedication, hard work, and patience, but with the right equipment, strategy, and marketing plan, you can turn your passion for printing into a successful business.

Question No.4 How to use a inkjet printer convert to dtf printer?

Most inkjet printer use the Epson printer head, and you can use it add the dtf ink to print on the film directly, after that you can shake the powder on the printed film side. But according to the market information, mostly the Epson 1390, Epson L1800 and Epson dx10 or Dx9 is more suitable fore converting to dtf printer.

Questions No.5 Is a dtf printer worth it ? How much is a dtf printer?

Whether a DTF printer is worth it for you depends on your specific needs and budget. DTF printers can range in price from several hundred dollars for entry-level models to several thousand dollars for high-end professional models. Additionally, there are ongoing costs associated with DTF printing, such as ink, film, and maintenance. PS: mostly Epson 1390 dtf printer price is around $1000, double dx9 head dtf printer price from $2500-$4000, for the Epson i3200 dtf printer price is around $5000 -$6000 with shaking machine.

If you are a small business or individual looking to print custom designs onto fabrics, a DTF printer may be a good investment for you. However, if you are just starting out, it may be more cost-effective to outsource your printing needs until you can afford to purchase and maintain a DTF printer.

Ultimately, it’s important to do your research and consider your specific needs and budget before deciding whether a DTF printer is worth it for you.

Questoins No.6 Can dtf only print on cotton ?

Dtf printer is not suitable to print on the cotton directly, but you can transfer on it. DTF (Direct-to-Film) printing can print on a variety of fabrics, including cotton, polyester, nylon, and more. DTF printing is a versatile printing method that allows for high-quality and vibrant designs to be printed onto a wide range of fabrics. If you want to print on the cotton directly, you can consider the dtg printer.

Questions No.7 Can you use sublimation ink for dtf printing ?

No. Sublimation ink is not typically used for DTF (Direct-to-Film) printing. Sublimation printing involves printing a design onto special transfer paper using sublimation ink, and then using heat and pressure to transfer the design onto a substrate that has a special coating that can absorb the ink. DTF printing, on the other hand, involves printing a design onto a special film using a printer, and then transferring the film onto the substrate using heat and pressure.

DTF printing requires special DTF ink, which is designed to adhere to the film and transfer well to the substrate during the heat press process. DTF ink is formulated differently from sublimation ink, and is optimized for use with the DTF printing process.

While it may be possible to use sublimation ink for DTF printing in some cases, it is not recommended as the results may not be as consistent or durable as with DTF ink. It is best to use the ink that is specifically designed for the printing method you are using to ensure the best possible results.

Questions No.8 Is dtf the same as screen printing ?

No, DTF (Direct-to-Film) printing is not the same as screen printing.

Screen printing involves the use of a stencil, or screen, which is placed over the substrate to be printed on. Ink is then pressed through the screen onto the substrate, creating the desired image. Screen printing can be used to print on a wide variety of materials, including textiles, paper, plastics, and metals.

DTF printing, on the other hand, is a relatively new printing method that involves printing a design onto a special type of film using a printer. The printed film is then transferred to the substrate using a heat press. DTF printing can be used to print on a variety of materials, including cotton, polyester, and blended fabrics.

Both screen printing and DTF printing can produce high-quality prints, but they use different methods and have different advantages and disadvantages depending on the specific application.

dtf printing Process

Questions No.9 Is dtf printing durable ? How long do dtf prints last ?

The firmness effect of DTF printing is very good. Generally speaking, if the surface of your product is not damaged, your pattern will not fade.

DTF printing can be durable, but the durability of the printed design will depend on several factors, such as the quality of the ink, the type of substrate, and the conditions to which the printed item will be exposed.

DTF ink is designed to bond well with the substrate during the heat press process, resulting in a strong and durable print. Additionally, the use of a film as a carrier for the ink helps protect the ink from rubbing off or fading over time.

However, the durability of the print can be affected by factors such as exposure to UV light, heat, and chemicals, as well as washing and wear. Proper care and maintenance of the printed item can help extend its lifespan.

Overall, DTF printing can be a durable printing method, but it is important to consider the specific application and take appropriate steps to ensure the best possible results.

Questions.10 Where can i buy the best dtf printer on the market ?

It is a good idea to do some research and read reviews from other users to get a sense of the quality and reliability of different models. You may also want to consider factors such as the availability of ink and replacement parts, as well as any warranty or service options offered by the manufacturer or dealer. Here we recommend you try to know Antprint hottest dtf printer AP-F1 with double Epson DX9 printer head.