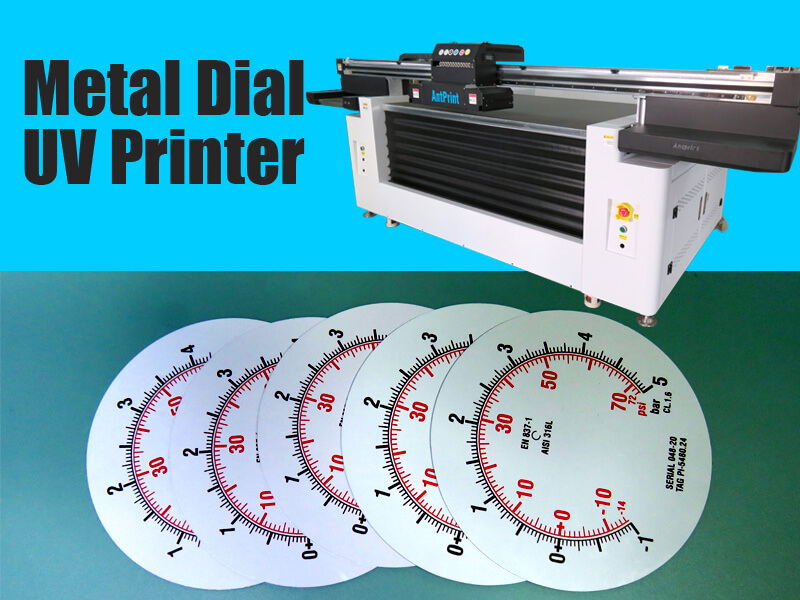

Direct To UV Printing On Metal Dial

Pressure UV Flatbed Printer Machine

Metal Dial UV Flatbed Printer

UV printer is a kind of multifunctional inkjet printing machine that can print on the metal surface directly, it work with uv ink that is sprayed onto the dial surface through the nozzle, and then irradiated by the ultraviolet curing lamp to cure and dry the ink instantly, thus forming a clear and firm pattern or text on the dial.

UV Flatbed Printer For Metal Dial Plate

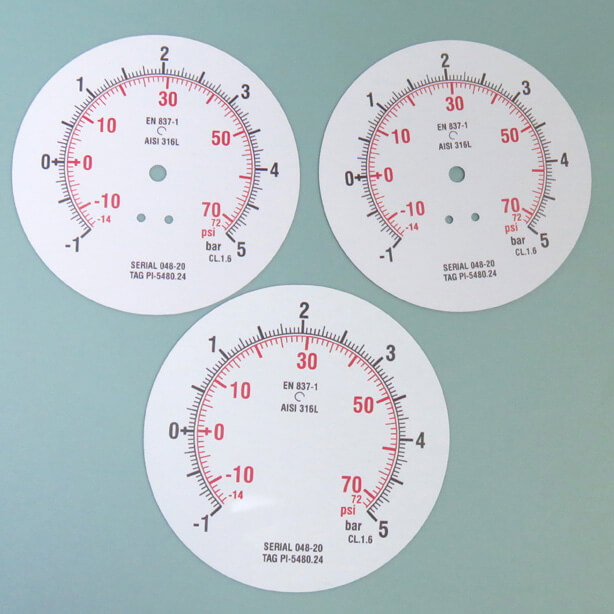

- Print directly on the metal dial, no need any pretreatment.

- Print with CMYK + W colorful image / text.

- Drying at once, no need to wait for drying after printing.

- UV Printing with 3d embossment effect (if you need).

Applicable materials: It can be printed on dials of various materials, such as metal dials, plastic dials, glass dials, ceramic dials, etc.

We can help customer to test samples for free, welcome to send inquiry to us today!

Metal Dial UV Printer Advantages

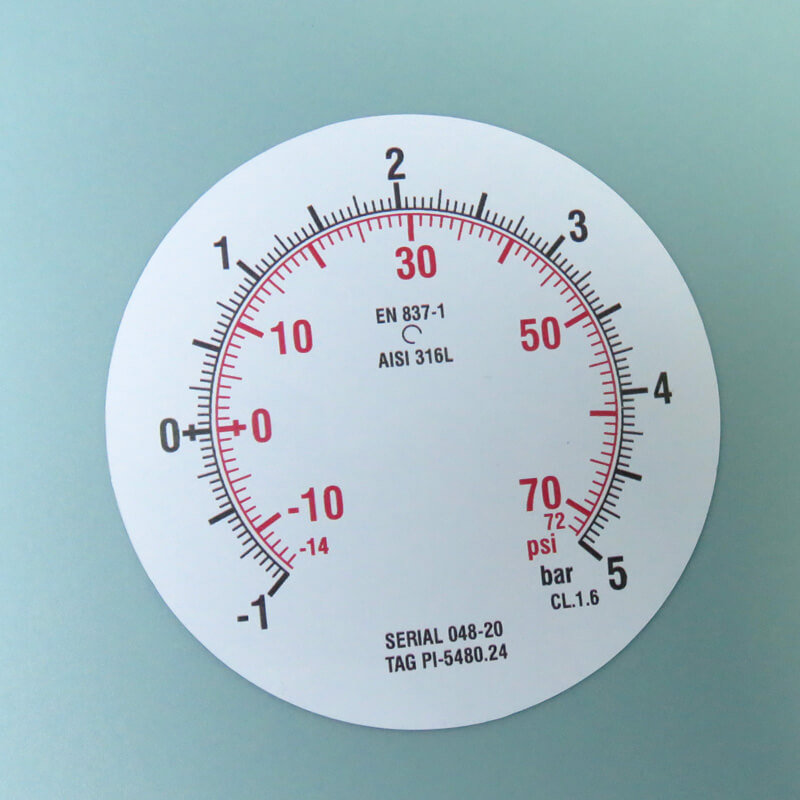

- It can achieve high-precision and high-resolution printing, with bright colors and high saturation,

- Print very delicate patterns and gradient effects;

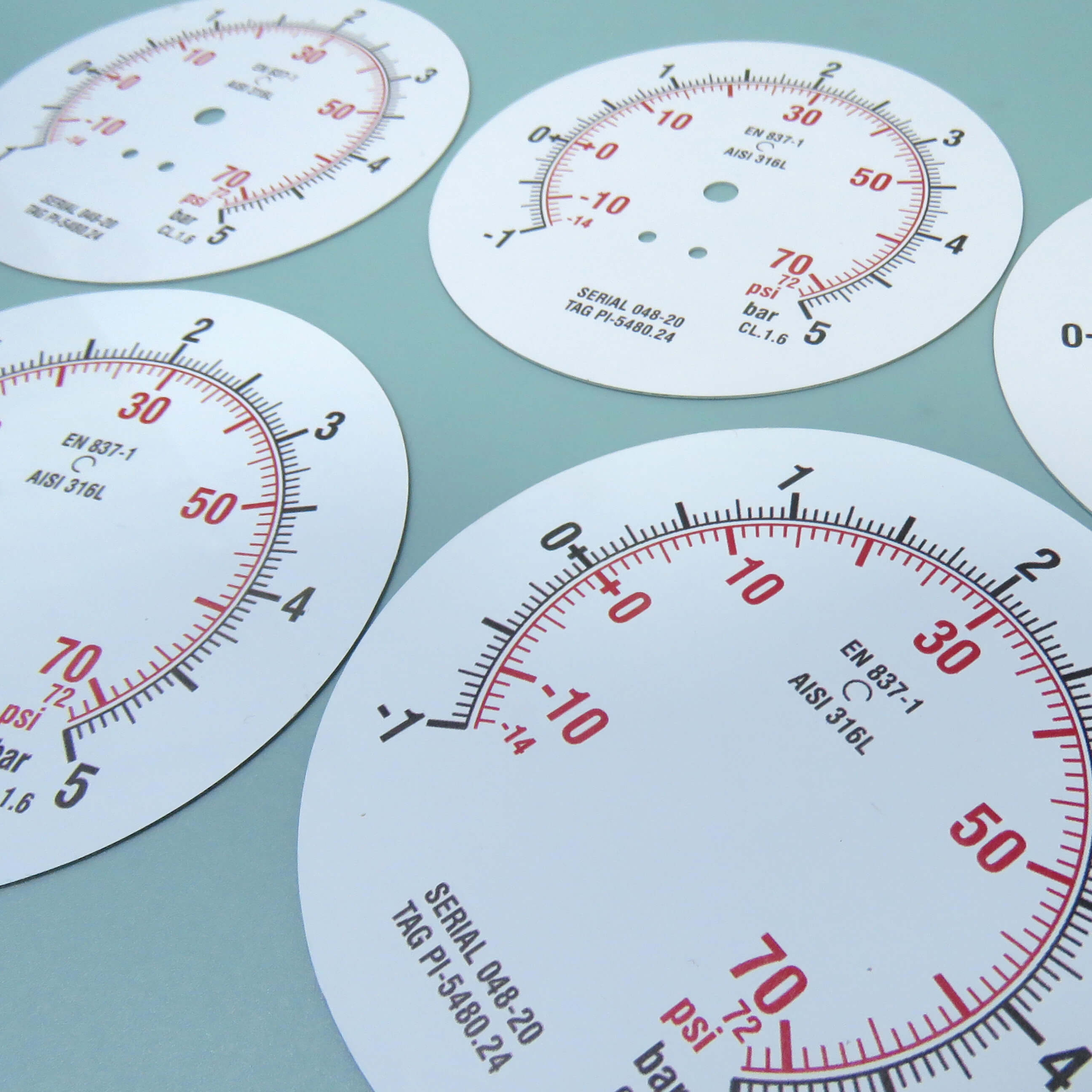

- Printing speed is relatively fast, which can meet the production needs of a certain scale;

- No plate making is required, and it can be designed and printed directly on the computer, which greatly shortens the production cycle and reduces costs, especially suitable for small-batch, personalized dial printing;

- Good environmental performance, UV ink has no volatile organic compound emissions

Dial UV Printer Application

Widely used in watch manufacturing, handicraft processing, gift customization and other industries. It can be used to make dials of various styles and themes, such as fashion watch dials, retro watch dials, pressure gauge, personalized customized dials, etc.

Metal Dial Plate Printer Working Process

- Design the pattern: Create or edit the dial pattern to be printed in computer graphic design software (such as Adobe Photoshop, Illustrator, etc.). You need to consider the size, scale, pointer position, brand logo, decorative elements and other aspects of the dial.

- Place the dial on the printer’s work platform, adjust the position and fix it.

- Send the print command in the printer operating software, and the printer starts working. The nozzle sprays UV ink onto the surface of the dial according to the preset pattern and parameters.

4. For some dials that need additional protection, a transparent protective coating can be applied to the surface of the printed pattern. This protective coating can increase the wear resistance, corrosion resistance and scratch resistance of the pattern and extend the service life of the dial.