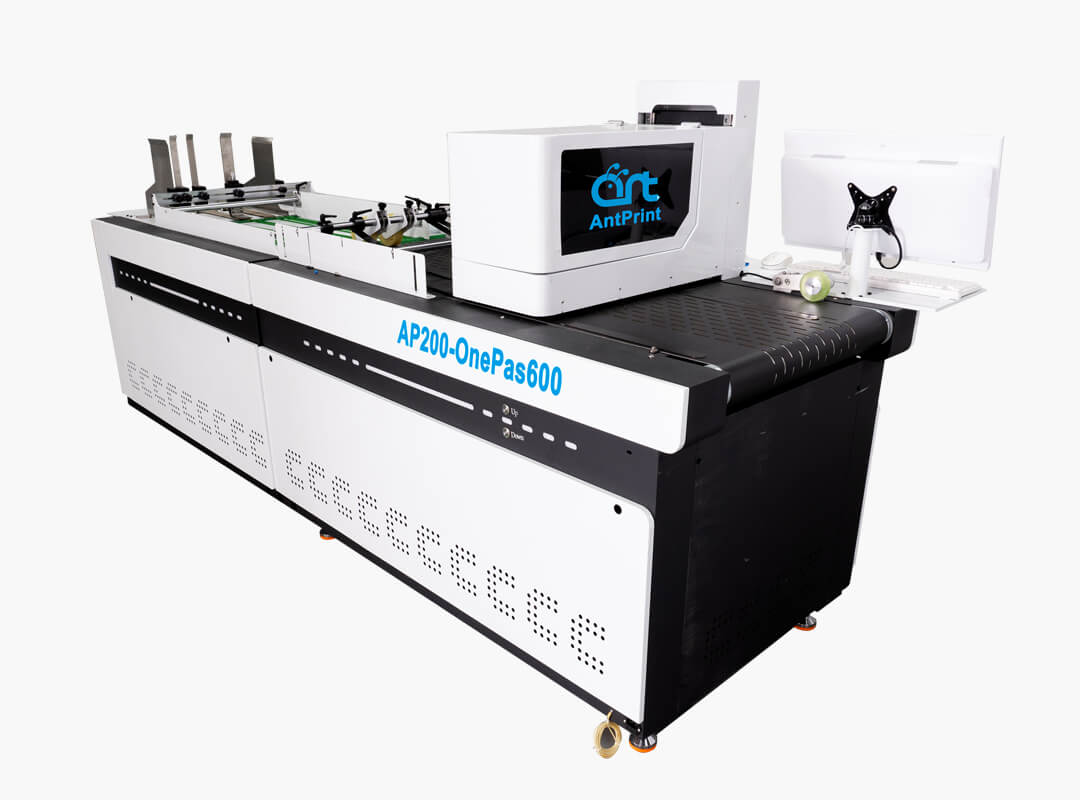

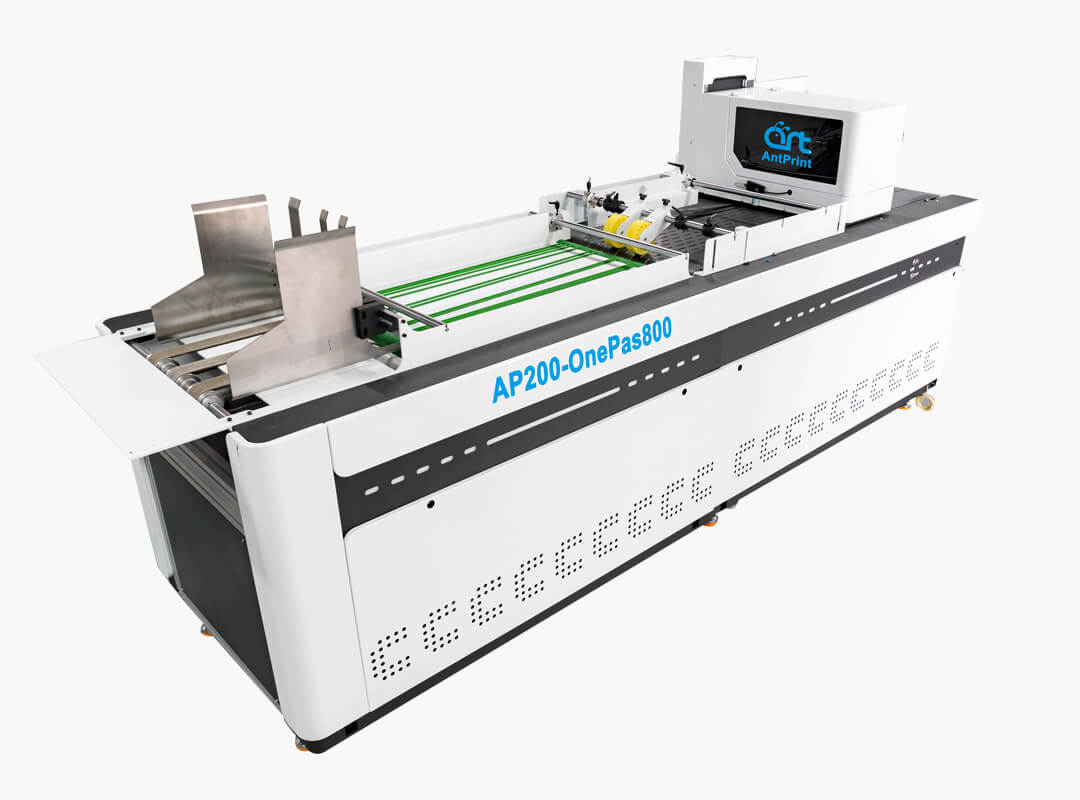

Single Pass Corrugated Pizza Box Paper Bags Digital Printing Inkjet Printer

High-quality single pass corrugated carton digital printing machine AP200-OnePas600 and AP200-OnePas800 are good at batch customized printing, using digital inkjet printing technology, environmentally friendly water-based ink (Dye ink or pigment ink), the max printing width can be up to 600mm or 800mm, no any length limit, benchmark accuracy up to 600dpi, faster printing speed up to 20m/minutes~40m/minutes, as the low ink cost and high quality performance, special for the company who need to personalized printing customized small and medium-sized batch orders!

- Very low ink cost: $0.09~0.14/ sqm

- Easy to custom printing: just edit your image in computer for custom printing directly.

- Simple operation system with auto feeding and receiving system.

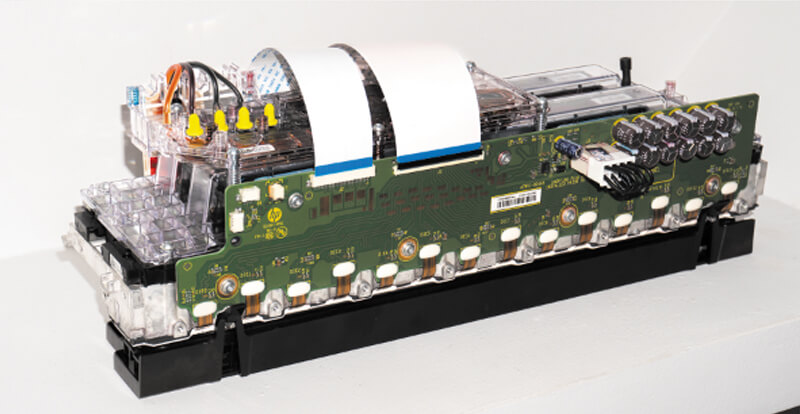

- Longer lifetime printer head as the HP pagewide printer head.

- Fast printing speed as run to 20-40 meter per minutes.

- Flexible printing that can meet your both small or large batch production demands.

AP200-OnePas800 Application

Corrugated printer not only can print on the corrugated box, but all the absorbent materials products, such as gift boxes, kraft paper food bags , Stationery , paper bags , biodegradable pulp boxes , cleaning rags , corrugated boxes, napkins, pouch, paper cup, cup sleeves , cartons, pizza box, white kraft paper, wooden wine boxes, gift bag, tissue, carton board, handbags, packaging boxes, Oil-proof bags, brochures, booklet, egg box, paper labels, paper cards, shopping bags and so on.

Corrugated Carton

Paper Bag

Pizza Box

Naptin / Tissue

Paper Pouch

Paper / cup Levees

Envelope

Kraft Food Paper Bag

Gift Box

Difference bettwen the dye ink and pigment ink

| Performance | Pigment ink | Dye Ink | Dark Pigment Ink |

|---|---|---|---|

| Waterproof Ability | Yes | No | Yes |

| Color Performance | Good for light materials | Good for light materials | Great for light materials |

Single Pass Corrugaed Digital Printer Advantages

- Convenient operation and very low printing cost

The carton printing system solution can be connected to the traditional packaging production line of the printing company to achieve the automatic production mode of the flow line, quickly realize the digital production transformation for the printing company, and the overall installation and operation are simple, and the whole operation process is intelligent.

- Customization and personalization are completely synchronized with production efficiency

With digital inkjet printing, relevant product/order information and images can be printed directly on the carton packaging, thus avoiding the time-consuming and error-prone process of multiple printing processes, and there is no need to stick labels on the carton packaging. At the same time, with digital inkjet printing, the message conveyed on the carton packaging can be changed very frequently, bringing endless possibilities, such as customizing and designing the text, images and other graphics on the carton packaging, so as to achieve customization and personalization and production efficiency.

start your custom printing business

- Synchronous improvement of printing quality and printing power

Due to the continuous innovation of nozzle technology, water-based inkjet ink, color management workflow software, and real-time, closed-loop color control, the printing quality of digital inkjet printing solutions is better than ever before. Color is an important part of a company’s image, and digital inkjet printing makes it possible to replicate precise company colors.

- Environmental attributes are further enhanced

Using digital inkjet, corrugated packaging materials can be produced according to actual needs, and packaging designs can be changed as many times as needed without excessive inventory. In addition, most corrugated materials can be recycled, achieving a high degree of sustainability.

How does the single pass printer works?

- Edit and set your design in your computer by Phothoshop and Printing sotware.

- Place the cardboards /paper bags on the feeding system.

- send printing task in via your printing software.

- Press “Start” on your printer operation panel.

- The printer will start to print automatically.

- Printing is completed

Different products printing videos

Single pass printing on coffee cup sleeves

Digital one pass inkjet printing on paper bags

Single pass printing on different size pizza boxs

Digital Single pass printing on the cotton bags

Digital Single Pass Printer Options

| Parameter | AP200-OnePas600 | AP200-OnePas800 |

|---|---|---|

| Printer head Quantity | Industrial HP A3 or A4 printer head (1-2 pcs printhead) | Industrial HP A3 or A4 printer head (1-4 pcs printhead) |

| Ink type | pigment ink or dye ink | pigment ink or dye ink |

| Max feeding width | 600 mm | 800 mm |

| Printer head | HP industrial printer head ( A4 or A3 model) | HP industrial printer head ( A4 or A3 model) |

| Printer head size | A4 with 27cm width, A3 with 35cm width | A4 with 27cm width, A3 with 35cm width |

| Available printing width | 21cm – 42cm | 21cm – 63cm |

| Print thickness | 150mm | 150mm |

| Feeding Method | 20-40 meter per minutes | 20-40 meter per minutes |

| Ink Color | CMYK | CMYK |

| Inkjet technology | Thermal Bubble Inkjet Technology | Thermal Bubble Inkjet Technology |

| Ink supply system | Continue ink supply system with secondary ink supply | Continue ink supply system with secondary ink supply |

| Resolution & Speed | 1200*1200pi-10 meter/minutes | 1200*600dpi-20meter/minutes |1200*300-40meter/minutes 1200*150-80meter/minutes | 1200*75-160meter/minutes | 1200*1200pi-10 meter/minutes | 1200*600dpi-20meter/minutes |1200*300-40meter/minutes 1200*150-80meter/minutes | 1200*75-160meter/minutes |

| Printer Structure | Steel frame structure gantry milling | Steel frame structure gantry milling |

| Power requirements | 110V-240Vac 50Hz -60 Hz

1000w electric consumption (max power) |

110V-240Vac 50Hz -60 Hz

1000w electric consumption (max power) |

| Print software | PrintEngineS | PrintEngineS |

| Working decibel | Less than 70 decibels | Less than 70 decibels |

| Graphic format | TIFF (RGB & CMYK), BMP, PDF, EPS, JPEG, AI, PSD, etc. | TIFF (RGB & CMYK), BMP, PDF, EPS, JPEG, AI, PSD, etc. |

| The Best working environment | 15℃-35℃, relative humidity 20%-80%

Avoid dusty environments, Avoid direct sunlight |

15℃-35℃, relative humidity 20%-80%

Avoid dusty environments, Avoid direct sunlight |

| Printer /Packing size | 152cm *88cm *137cm / 164cm *98cm *157cm | 152cm *104cm *134cm / 165cm *120cm *157cm |

| Printer N.W. /G.W. | 250kg / 322kg | 290kg / 370kg |

| Feeding system / packing size | 135cm *88cm *124cm / 140cm *98cm *135cm | 131cm *107cm *124cm / 143cm *120cm *135cm |

| Feeding system / N.W. /G.W. | 177kg / 235kg | 179 kg / 230kg |

| Applicable material | Corrugated paper, cardboard, coated paper, kraft paper and other full range of packaging surface papers | Corrugated paper, cardboard, coated paper, kraft paper and other full range of packaging surface papers |

More Details About The Single Pass Printer

Automatic Feeding System

The movable material fixing fixture can be easily

positioned to free your hands

Automatic ink pump

Automatically pumps ink quickly when powered on

and alarms when ink is low

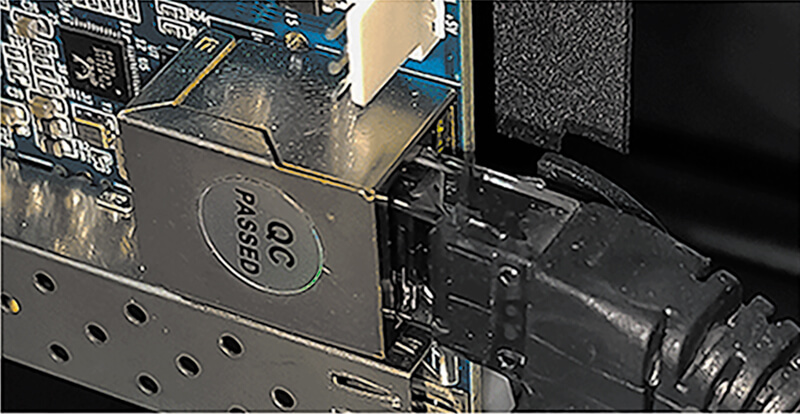

Industrial-grade printhead

High image quality and stable performance

Positioning and deviation correction

Stable attachment and easy positioning during feeding

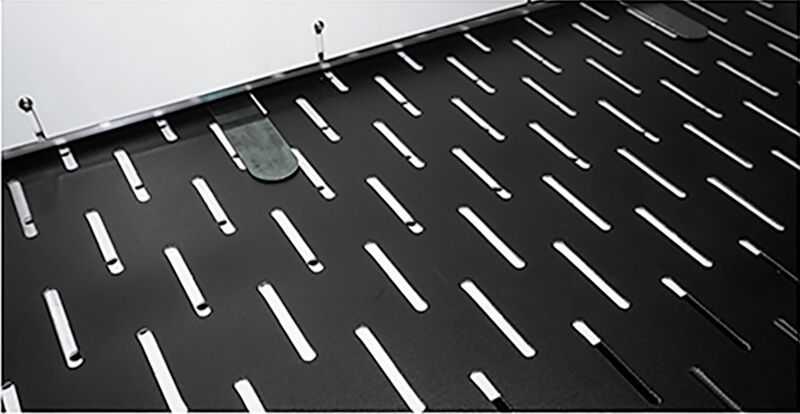

Adsorption crawler

1000+ suction port adsorption & Bidirectional conveying

Network cable port

Network cable connected devices are not prone to signal loss