Best Flatbed UV Printer For Acrylic Glass Wood | AP200-1613

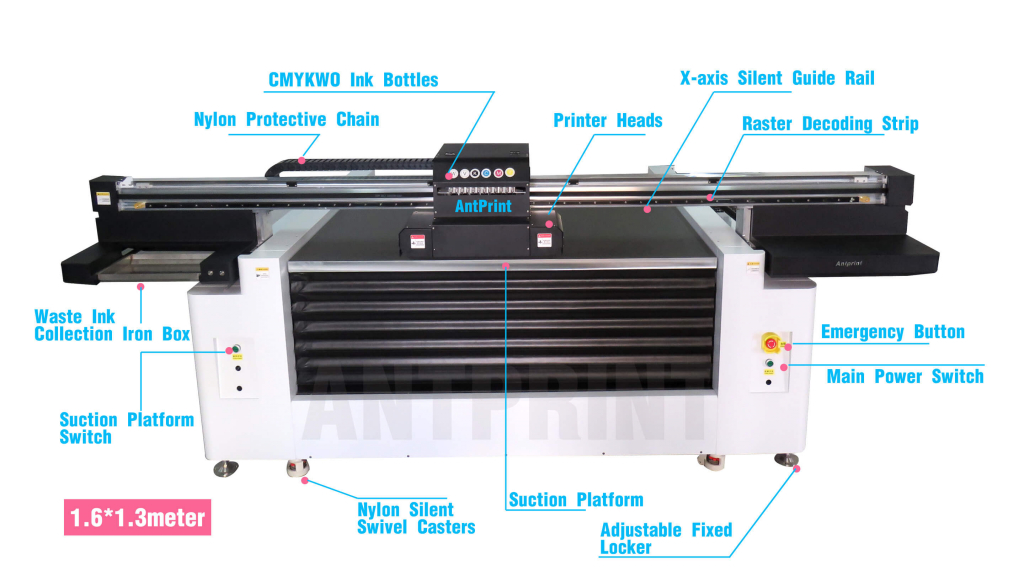

AP200 series uv printer is ANTPRINT big format series flatbed printer, the max printing format up to 1.6 * 1.3 meter, max thickness up to 50cm. If you are going to do the uv printing for acrylic, glass or wood, it will be the best option for you!

In order to help more customers to do the flatbed uv printing, ANTPRINT make a reasonable price, which can help the business man start the printing business!

antprint brand 1613 uv led flatbed printer

AP200-1613 UV Printer Show Video

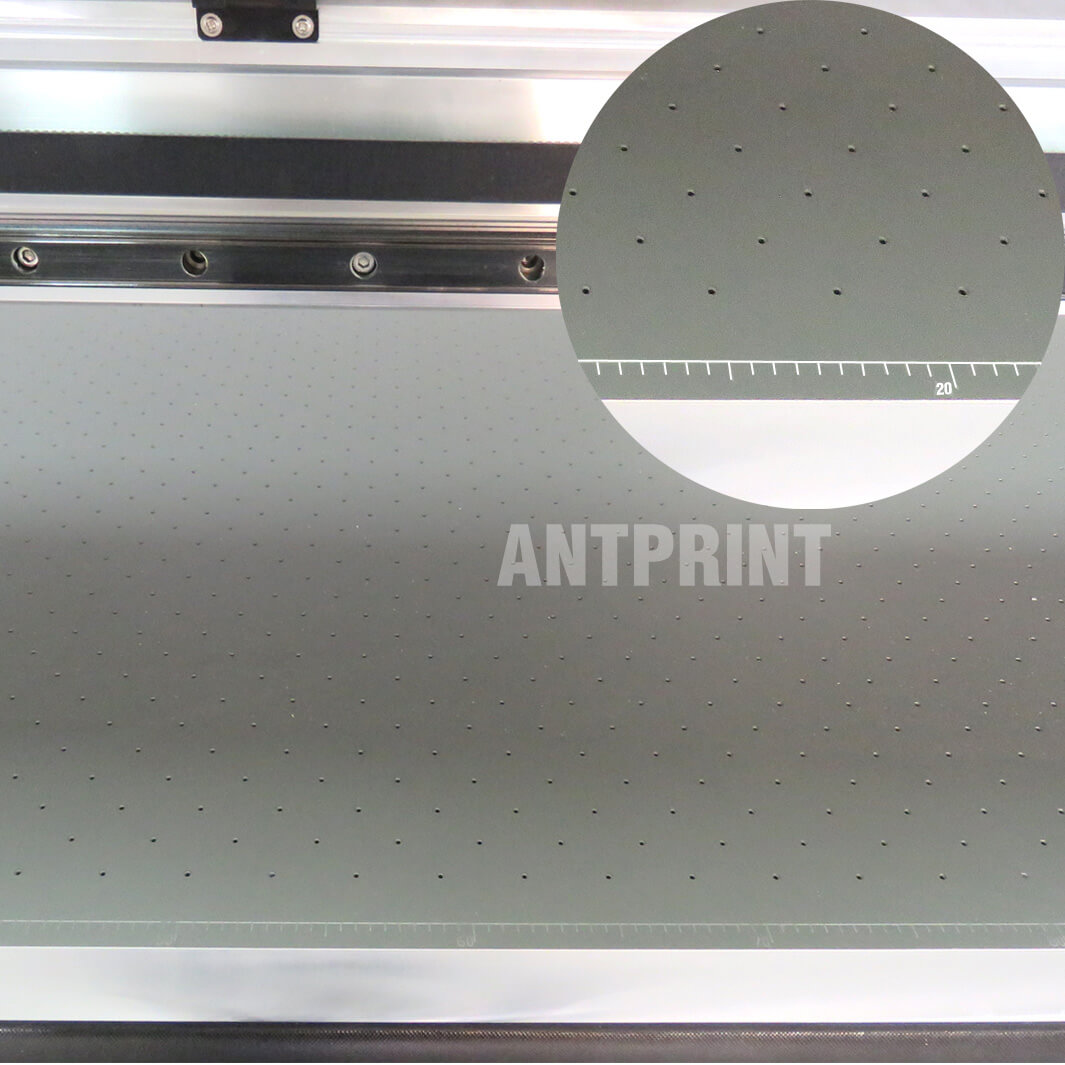

Vacuum Suction Platform

Easy to uv print for acrylic, pvc and other easily deformed materials.

UV flatbed printers used to be glass platforms, 1613 uv printer is easy to print on the wood and glass heavy materials, but some customers need to print soft materials, such as thin acrylic, PVC and materials that are easily deformed. Therefore, the vacuum adsorption platform came into being. The air suction platform is an important part of the UV flatbed printer, which makes the printing process more stable and the printing effect better.

The large-format UV printer ANTPRINT 1613 has optimized the vacuum adsorption platform, which not only ensures that the performance of the platform is not affected, but also enables large and uniform suction at any position on the platform. There are various treatment processes for the surface of the vacuum platform, namely fluorocarbon, anodizing and hard oxidation, which can be selected according to actual needs. Among them, the fluorocarbon process is the most scratch-resistant, wear-resistant and corrosion-resistant. Its external hardness can reach HV500-700, which can effectively avoid corrosion of the platform by pre-pressed materials.

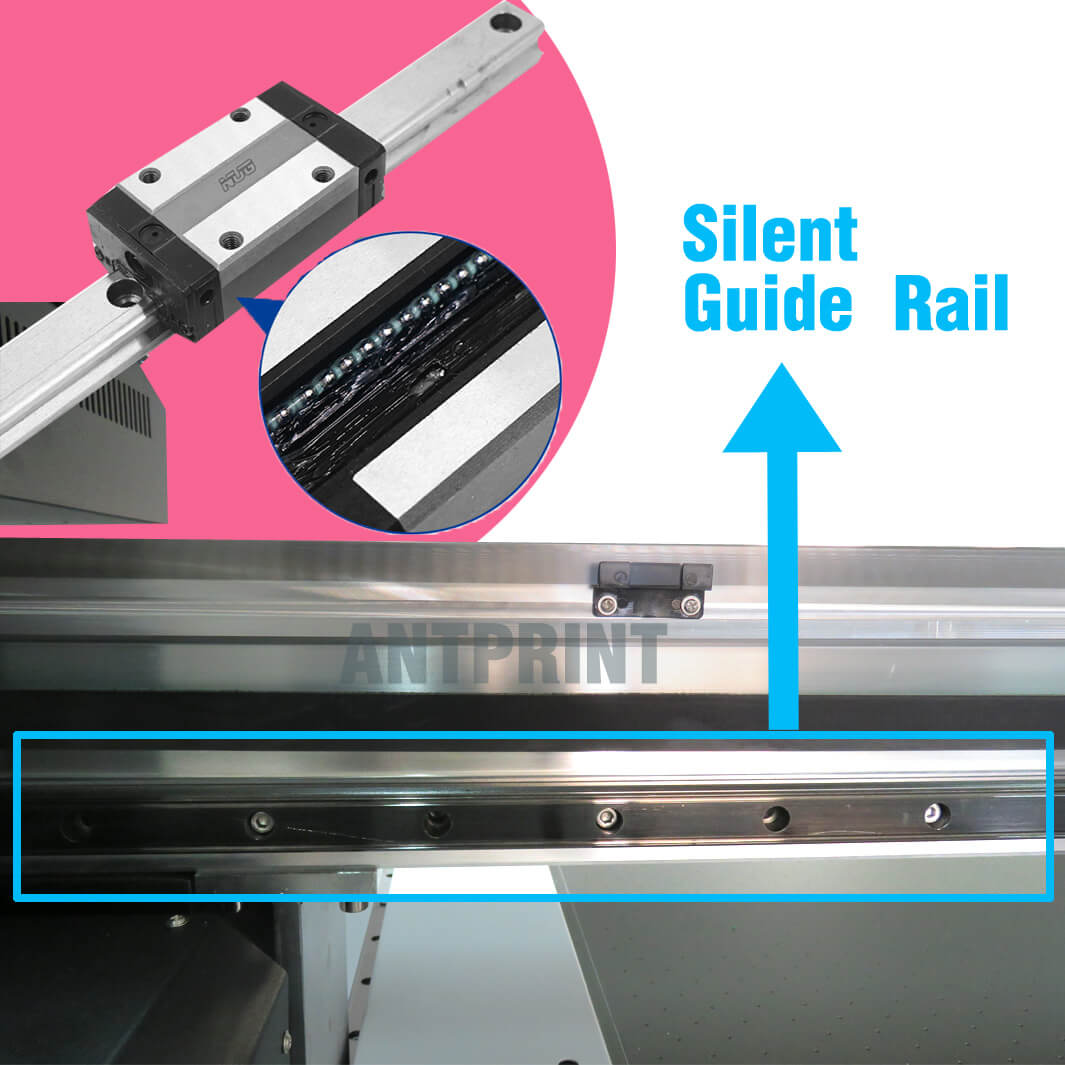

Silent Guide Rails

Smooth And Low-Noise Operation

The guide rail itself is one of the important components of the flatbed printer, controlling the smooth operation of the machine. Uv printing machine have very high requirements for the quality of the guide rails. After all, the weight of components such as the character carriage and UV system are pressed on the guide rails. Guide rails with poor quality will become deformed and worn over a long period of time, seriously affecting the operation of the machine and resulting in poor printed pattern effects.

The printer uv AP-1613 digital printer adopts silent guide rail configuration for both the It is produced in a machining center and processed in one go to ensure the high precision requirements of the whole machine. The silent guide rails are used to effectively reduce the noise in the working environment.

UV Inkjet Printer Locking Feet

Nylon Silent Swivel Casters

Nylon is wear-resistant and environmentally friendly, has low noise, and has a strong load-bearing capacity. The height can be adjusted by rotating the screw left and right; the universal wheel is made of anti-skid material, which is wear-resistant and stable, making it convenient for flatbed UV inkjet printer operators to move the printer lightly and effortlessly!

304 stainless steel adjustable fixed anti-slip foot cup chassis

High strength, wear-resistant and corrosion-resistant, durable, and has good anti-oxidation and anti-corrosion capabilities even in humid environments; in addition, the flatbed uv printer thickened base provides stable support and large load-bearing capacity!

Microcomputer Digital Temperature Controller

uv led printer’s Intelligent protection system

Automatic real-time collection and monitoring of specific data of the surrounding environment through temperature sensors. When the ambient temperature exceeds the preset value of the temperature controller, automatic control of the temperature hysteresis can be set. If the temperature is still rising, when it reaches the over-limit alarm temperature point set by the temperature controller, the over-limit alarm function will be automatically activated to protect the 1613 uv led printer and UV system more intelligently.

Negative Pressure System

more stable uv ink supply system

The negative pressure system of the flat uv printer has two main functions:

1. Adsorb the ink of the nozzle so that the ink of the nozzle will not flow by itself, so as to avoid ink dripping, damaging the printing effect and causing unnecessary waste.

2. The negative pressure system can also suck the uv ink in the ink cartridge to the secondary ink cartridge, so that no matter where the ink cartridge is, there will be no printing disconnection, backflow, color cross-talk, etc.; So, there is no need to worry about adding too much ink in your uv printer machine, adding too little, etc. question.